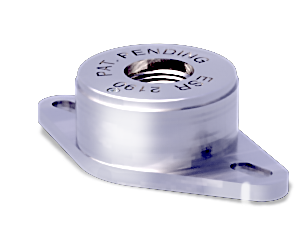

CNX Cinch Nut is designed to limit story drifts of multi-story buildings and eliminate additional structural damage caused by loose connections in floor framing.

Cinch Nut

CNX-Series Advantages

- Features perpetual ratcheting along the length of a threaded rod that is not limited like the energy stored in a spring loaded device.

- Simple, one-time installation that does not require pin or screw activation after the building is loaded.

- CNX models are matched to the rod diameter specified for optimal tolerances.

Code Reports

- ESR-2190

- LA City RR 25623

- FL 17456 Florida Building Code – Building

- Florida Building Code Residential

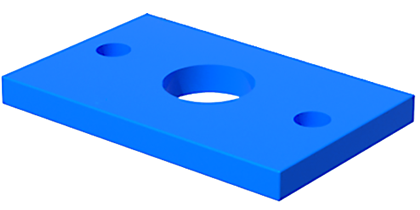

Bearing Plate Washer (BPW)

Z4 Bearing Plate Washers (BPW) are the interface between the Tie-Down System and the level of the building being anchored to the foundation. As the floor system is pulled upward by shear wall over-turning forces, pressure is applied to the BPW/CNX assembly and transferred into the all thread rod (ATR). The required bearing area is based on the design uplift to minimize crushing of the wood and the plate thickness must be sufficient that bending does not limit the capacity of the system. The wood species is also a factor when sizing. The pounds per square inch (psi) of compression cannot exceed the allowable compression perpendicular to the grain of the wood species it is bearing on.

Coupler

The Z4 Tie-Down System begins by connecting the first level threaded rod to the hold down anchor in the foundation with a Coupler. At upper levels Couplers are used to connect threaded rod end to end to create a continuous load path. Reducers are Couplers that connect two rods that are different diameters.

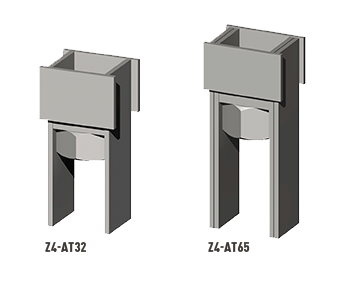

Anchor Tie (AT)

The Anchor Tie is a structural component designed for connecting Z4 Tie-Down Runs to steel members. Anchor Ties are fabricated from ASTM Grade A36 steel plate and include a pre-welded nut, making the Tie-Down connection quick and easy. ATs are available in 9 and 12 inch heights. Other heights available upon request. The 9 inch version with 1/4 inch plate steel legs is available for connecting 5/8” through 1-1/2” diameter threaded rod and the 12 inch version with twice the steel thickness at the legs is used for connecting up to 2” diameter rod.

Common applications include connecting to steel plates at concrete decks and steel beams where Tie-Down runs terminate.

- When installing at concrete decks, steel plates are designed by the Engineer of Record to resist the uplift loads.

- After concrete is poured, the AT is welded to the plate and a threaded rod is connected to the Anchor Ties’ pre-welded nut enabling the Tie-Down Run from above to attach.

- Steel beam installations are designed by the EOR.

- The Anchor Tie is welded to the beam prior to floor framing then attachment of the threaded rod and Tie-Down Run completes the installation.

Z4 Tension Tie (T2)

The Z4 “T2” is a steel tube with a steel end plate welded to one end designed to transfer tension forces with a single concentric hold-down device. Sandwiched Installations are made by through bolting two wood members with a T2 between. The tube is then attached to a threaded rod to transfer the tension loads.