Pre-fabricated MiTek Moment Frames installed in existing structures to resist lateral earthquake forces.

Soft story

Overview

THE NEED TO STRENGTHEN SOFT STORIES IN HIGH SEISMIC ZONES

Whether required by an ordinance, or chosen to increase the resiliency of a building, MiTek Hardy Shear Wall Systems provide solutions.

RETROFIT ORDINANCES ARE IN PLACE NOW

Some buildings will require retrofit by 2017

For San Francisco, according to the Structural Engineers Association of Northern California the USGS predicts that there is a 63% chance another large earthquake will strike San Francisco in the next 30 years. “The intensity is expected to rival those of the 1989 Loma Prieta Earthquake.”

It is estimated that 43% to 85% of soft-story buildings will be uninhabitable following a major earthquake, potentially displacing 58,000 residents, 2,000 businesses, and 7,000 employees.

13,500 Buildings will be affected

4 cities have adopted soft-story retrofit ordinances

As of today, these following cities have adopted soft-story retrofit ordinances that require building owners to make improvements: San Francisco, Berkeley, Oakland, and Los Angeles. There is already talk about other California cities adopting similar laws.

Cities are directly notifying the building owners of their obligations under the new laws, and those names and addresses are a matter of public record, should entrepreneurial contactors want to market their retrofit services.

It is estimated in L.A., that upwards of 13,500 buildings may need code-approved retrofits.

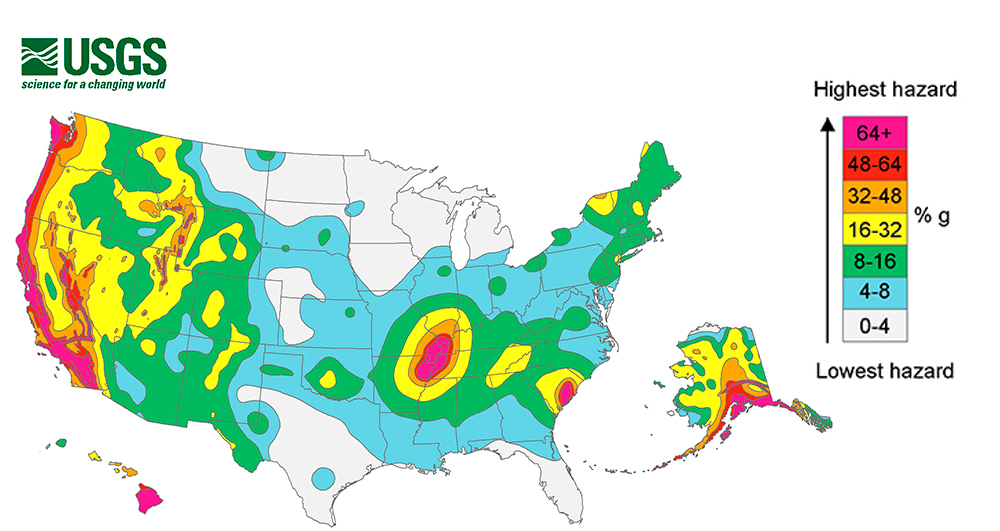

HIGH SEISMIC ZONES

Geological conditions and historical earthquakes help us to identify and classify high seismic zones. Earthquakes such as the 1987 Whittier, 1989 Loma Prieta, 1994 Northridge, and 2001 Nisqually, Washington have caused extensive damage to thousands of wood-framed homes. The resulting damage has helped to advance new products and methods that improve the structural integrity of buildings.

After years of study, code officials in the San Francisco Bay Area and in Los Angeles have recently adopted ordinances that require soft-story seismic retrofits. The purpose is to prevent loss of life, to mitigate possible building collapse and to avoid the inhabitants being displaced from a condemned building.

Why MiTek Hardy Moment Frames?

The MiTek Special Moment Frame is a state-of-the-art, pre-fabricated, pre-engineered system that utilizes the new-generation SidePlate® moment connection technology to resist lateral forces from high wind and earthquake loads.

The Hardy Moment Frame is pre-assembled and welded at the factory, then delivered to the job site ready to install in new construction or existing structures as a retrofit to improve the buildings ability to resist earthquake forces for better safety and damage control.

- Approved by AISC’s Connection Preapproval Review

- Panel (CPRP) in AISC 358 Prequalified Moment Connection Standard.

- Meets code – third party agency evaluation for alternate materials is not required.

- Lateral bracing of the beam is not required.

- Standardized sizes with Pre-engineered designs for easy specification.

- Custom Moment Frame designs available.

- For use in residential, commercial and industrial.

- An ideal solution for soft-story retrofits.

Pre-fabricated for easy installs to save time and money.

The Process: Pre-Assembled Installation at an Existing Condition

1. Dig the Footing

For pad footings dig the foundation where the columns with hold down anchors will be located. The Engineer of Record may require larger footings. Digging the footing a little deeper not only assures meeting code for moisture, it also makes installation of the Hardy Portal Frame and anchors in retrofit applications easier.

2. Prepare the Template Kit

For anchorage, the Template Kit shown includes two Templates, two Bolt Braces, eight anchors, with two washers and four nuts per anchor and rebar shear ties. The Template has a slotted hole at two ends, which are used to measure the inside “steel-to-steel” dimension of the Hardy Poral Frame.

3. Delivery of the Moment Frame

The MiTek Hardy Portal Frame is delivered to the jobsite completely pre-assembled with wood nailers attached. There is no field assembly, no field welding and therefore no required special inspection for the Frame assembly.

4. Installing the Frame

With the footings prepared and shoring in place, the site is ready for installation of the Hardy Portal Frame. Tilt the top of the Frame back, away from the building then move it towards the point of installation with the column bases forward. Lower the column bases into the foundation, and then raise the beam until the Frame is vertical.

5. Position the Frame

Raise the Frame up and position it in the wall line. For retrofit applications with the Frame installed within the existing line, raise the Frame until the 3x nailer on top of the beam is in contact with the building collector and install temporary shoring.

6. Installing Anchorage

The anchorage can now be installed at the column base plates and suspended in the open footing. The Bolt Brace that is visible at the embed end assures the anchors will not sway independently while pouring concrete to keep them parallel and plumb. The rebar reinforcement shown is designed by the Engineer of Record.

7. Frame in Place

The MiTek Hardyl Portal Frame is installed and ready for concrete to be poured at the footings. Connectors to transfer shear will be framing angles as specified by the Engineer of Record. The label shown on the left column provides illustrations of typical bottom and top connections for the installers and the building inspector’s reference.

8. Fixed Base Installation

Fixed base applications doubles the frame capacity.

9. Interior Installation

When fitting into an existing space, splice columns assemblies are available.